In the world of metal fabrication, carbon arc gouging stands out as a versatile and efficient method for cutting, shaping, and removing unwanted metal. This process involves using a carbon arc to melt and remove metal, leaving behind a clean and precise cut. Understanding the setup and techniques for carbon arc gouging is crucial for achieving optimal results. In this comprehensive guide, we will explore the principles, advantages, setup, safety measures, equipment selection, techniques, common mistakes to avoid, and applications of carbon arc gouging.

What is carbon arc gouging?

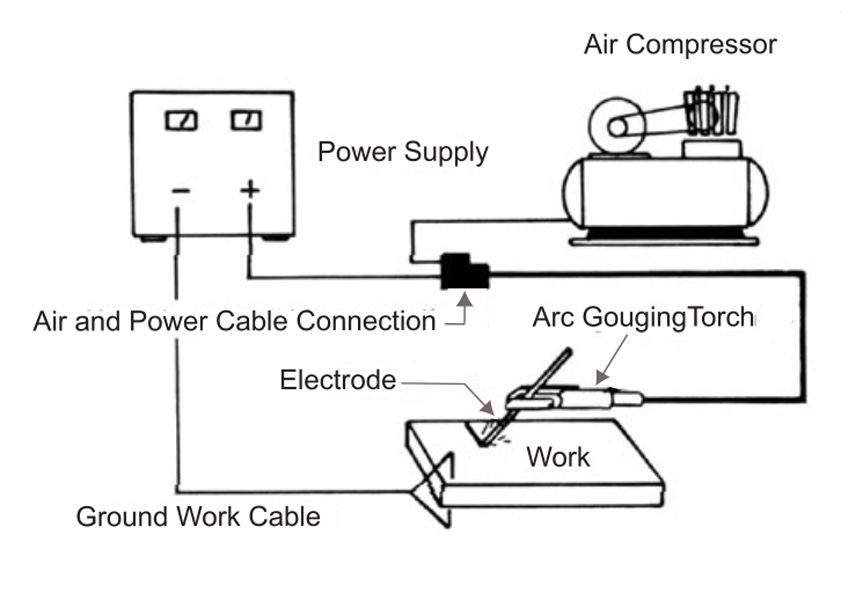

Carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon electrode and the workpiece. The intense heat generated by the arc melts the metal, while a continuous blast of air blows away the molten metal, creating a clean groove. This method is commonly used for removing defective welds, preparing welding joints, and cutting and shaping various types of metal.

Carbon arc gouging is a versatile process that can be performed on a wide range of metals, including carbon steel, stainless steel, aluminum, and copper alloys. It offers significant advantages in terms of speed, precision, and versatility, making it a preferred method in industries such as shipbuilding, construction, and manufacturing.

The principles of carbon arc gouging

At the heart of carbon arc gouging is the principle of using electrical energy to create intense heat, which in turn melts the metal. The carbon electrode serves as the conductor of the electric arc and is consumed during the process. The molten metal is removed by the force of the high-velocity air stream, leaving a clean groove with minimal distortion to the surrounding metal.

The efficiency of carbon arc gouging lies in its ability to rapidly remove large volumes of metal while maintaining precise control over the depth and width of the cut. This makes it an ideal method for preparing surfaces for welding, removing excess material from castings, and repairing or modifying metal components.

Advantages of carbon arc gouging

One of the primary advantages of carbon arc gouging is its ability to remove metal rapidly and efficiently, making it a cost-effective solution for various metal fabrication tasks. Unlike traditional mechanical methods such as grinding or chiseling, carbon arc gouging produces minimal smoke, fumes, and noise, creating a cleaner and safer working environment.

Additionally, carbon arc gouging can be performed on a wide range of metal thicknesses, making it suitable for both light-duty and heavy-duty applications. The process also offers excellent maneuverability, allowing operators to access tight spaces and intricate geometries with ease. With proper setup and technique, carbon arc gouging can deliver smooth, clean cuts with minimal post-processing requirements.

Carbon arc gouging setup

A successful carbon arc gouging setup begins with selecting the right equipment and preparing the work environment. The first step is to choose the appropriate carbon electrode, taking into account the material to be gouged, the required depth of cut, and the available amperage. The size and shape of the electrode play a crucial role in achieving the desired results, and various options are available to suit specific applications.

Next, attention should be given to adjusting the amperage settings on the welding power source. Proper amperage selection is essential for controlling the depth and width of the groove while preventing overheating and excessive electrode consumption. It is recommended to refer to the equipment manufacturer’s guidelines and conduct a test run to fine-tune the settings for optimum performance.

Creating a safe working environment is paramount when setting up for carbon arc gouging. Operators should wear appropriate personal protective equipment, including eye protection, gloves, and flame-resistant clothing. Adequate ventilation and fume extraction systems should be in place to minimize exposure to airborne contaminants. Furthermore, ensuring proper grounding of the workpiece and maintaining a clear workspace are critical for safe and efficient operation.

Safety measures for carbon arc gouging

While carbon arc gouging offers numerous benefits, it also presents potential hazards that must be addressed through comprehensive safety measures. The intense heat generated during the process can produce harmful fumes and ultraviolet radiation, requiring operators to take precautions to protect themselves and others in the vicinity.

Proper ventilation is essential for removing airborne contaminants and maintaining air quality in the work area. Ventilation systems should be strategically positioned to capture and exhaust fumes and smoke effectively. Operators should be trained to recognize the signs of exposure to hazardous fumes and take necessary precautions to minimize health risks.

In terms of personal protective equipment, operators should wear a suitable respirator to protect against inhalation of fumes and particulates. Eye protection in the form of safety glasses or a face shield is crucial for shielding the eyes from intense light and potential splatter. Gloves made from heat-resistant materials provide protection against burns and electric shock, while flame-resistant clothing offers an additional layer of defense.

Choosing the right equipment for air carbon arc gouging

Selecting the right equipment is a critical aspect of preparing for air carbon arc gouging. The choice of welding power source, carbon electrodes, and air supply equipment can significantly impact the quality and efficiency of the gouging process. When selecting a welding power source, factors such as amperage output, duty cycle, and portability should be considered to meet the specific requirements of the application.

Carbon electrodes come in various diameters and lengths, each suited to different gouging tasks. The selection of the electrode size and shape should be based on the desired groove dimensions, material thickness, and access limitations. The quality of the carbon electrode material and the presence of any coatings or impurities can affect the performance and longevity of the electrode.

The air supply system plays a crucial role in delivering the high-velocity air stream required for removing the molten metal. An air compressor with adequate airflow capacity and pressure regulation is essential for achieving consistent and efficient gouging results. Proper maintenance and filtration of the compressed air can help prevent contamination and ensure reliable operation of the gouging equipment.

Techniques for effective air carbon arc gouging

Mastering the techniques of carbon arc gouging is essential for achieving precision, efficiency, and control over the metal removal process. Proper hand-eye coordination, electrode manipulation, and body positioning are key elements of successful gouging techniques. Operators should strive to maintain a steady and consistent arc length while moving the electrode at a controlled speed to achieve the desired groove geometry.

The angle of the carbon electrode relative to the workpiece surface plays a crucial role in determining the width and cleanliness of the gouge. A shallow angle produces a wider groove, while a steeper angle results in a narrower cut with greater precision. Operators should practice adjusting the angle to suit the specific application and achieve the desired results.

Maintaining a smooth and continuous motion during gouging helps prevent irregularities and uneven depth in the groove. Operators should strive for uniformity in the gouge profile, avoiding sudden stops or hesitations that can lead to rough edges and surface imperfections. By mastering the art of consistent and controlled movement, operators can achieve smooth, clean cuts with minimal rework requirements.

Common mistakes to avoid in carbon arc gouging

While carbon arc gouging offers numerous benefits, it also presents potential pitfalls that can compromise the quality and efficiency of the process. One common mistake is using the wrong size or type of carbon electrode for the application, which can result in inefficient metal removal, excessive electrode consumption, and poor gouge quality. It is essential to match the electrode specifications to the specific requirements of the task at hand.

Inadequate amperage settings can also lead to suboptimal gouging performance, causing issues such as insufficient metal removal, overheating, or electrode sticking. Operators should take the time to carefully adjust the amperage settings based on the material thickness, electrode size, and desired groove dimensions. Conducting test runs and making incremental adjustments can help fine-tune the settings for optimal results.

Another common mistake is neglecting proper ventilation and fume extraction, which can lead to exposure to hazardous fumes and compromise air quality in the work environment. Operators should prioritize the implementation of effective ventilation systems and use appropriate personal protective equipment to mitigate health risks associated with fume inhalation and ultraviolet radiation exposure.

Applications of air carbon arc gouging

Carbon arc gouging finds widespread application in various industries and metal fabrication processes, thanks to its versatility, speed, and precision. In shipbuilding and repair, carbon arc gouging is used for removing old welds, preparing surfaces for new welds, and cutting and shaping metal components with ease. The process is also employed in the construction industry for fabricating structural steel, removing excess material from castings, and performing repairs and modifications on metal structures.

In the manufacturing sector, carbon arc gouging is utilized for a wide range of tasks, including removing defects from castings, preparing welding joints, and shaping metal parts to precise specifications. It is also applied in the maintenance and repair of heavy machinery, where the ability to rapidly remove large volumes of metal makes it an efficient method for addressing wear and damage on critical components.

Final Thoughts

As we conclude our comprehensive guide to carbon arc gouging setup, it is evident that this metal removal process offers unparalleled versatility, efficiency, and precision for a wide range of metal fabrication tasks. By understanding the principles, advantages, setup requirements, safety measures, equipment selection, techniques, common mistakes to avoid, and applications of carbon arc gouging, operators can elevate their skills and achieve exceptional results in metal cutting, shaping, and repair.

With the right setup and mastery of the techniques, carbon arc gouging empowers metal fabricators to tackle challenging tasks with confidence and precision, delivering clean cuts and smooth surfaces with minimal effort. By harnessing the power of carbon arc gouging, operators can unlock new possibilities in metal fabrication and create high-quality components that meet the most demanding specifications. So, embrace the art of carbon arc gouging setup, and unleash its full potential in your metal fabrication endeavors.

Mastering at setup and techniques of carbon arc gouging

Mastering the setup and techniques of carbon arc gouging can elevate your metal fabrication skills to new heights, enabling you to achieve precise and efficient metal cutting, shaping, and repair. With the right equipment, safety measures, and application of best practices, carbon arc gouging becomes a valuable asset in your metal fabrication toolkit, offering unmatched versatility and performance for a wide range of tasks. So, embrace the power of carbon arc gouging setup and unleash its full potential in your metal fabrication endeavors.