Welding is a complex process that requires skill, precision, and attention to detail. When you are working for sanitary pipe welding, the stakes are even higher. The quality of the weld can directly impact the safety and integrity of the product being transported through the pipe. In this guide, we will share tips and tricks to help you hone your skills and achieve a flawless finish every time. Whether you are a seasoned welder or a beginner, this guide will provide you with the essential information you need to master the art of sanitary welding.

About sanitary pipe welding

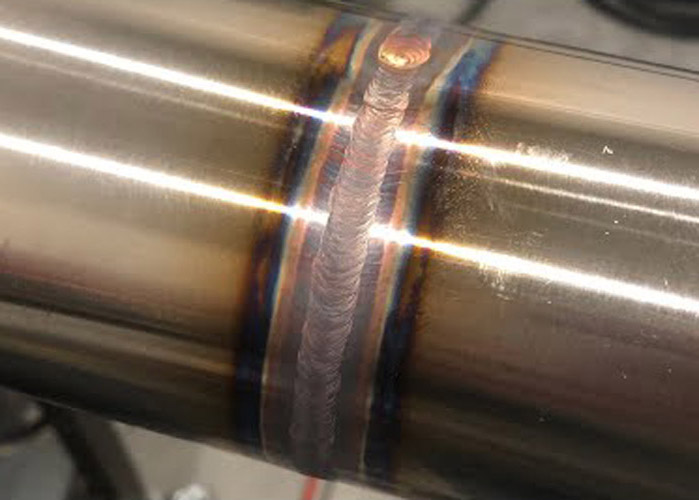

Sanitary pipe welding is the process of joining two pieces of tubing in a way that meets specific sanitary standards. Sanitary tubing is typically used in industries where hygiene is essential, such as food and beverage, pharmaceuticals, and biotech. The weld must be smooth and free of any crevices or pits where bacteria can grow. Sanitary welding is also critical for maintaining the integrity of the pipe .

Important of sanitary welding

Sanitary welding is essential for maintaining the integrity and safety of the product being transported through the tube. In industries where hygiene is critical, such as food and beverage or pharmaceuticals, a single point of failure can have catastrophic consequences. A poor weld can create crevices or pits where bacteria can grow, leading to contamination of the product. Sanitary welding is also essential for maintaining the structural integrity of the tube, ensuring that it can withstand the pressure and stress of transportation.

Types of welding machines are used

There are several types of welding machines used for sanitary pipe welding, including TIG welding, MIG welding, and orbital welding. TIG welding is the most commonly used method for sanitary welding due to its precision and ability to produce a high-quality, smooth weld. MIG welding is also used but is less common due to the potential for spatter and the need for post-weld cleaning. Orbital welding is used in industries where a high level of automation is required, such as in the biotech industry.

Materials used for sanitary welding

The materials used for sanitary pipe welding depend on the industry and the product being transported through the pipe. Stainless steel is the most commonly used material due to its durability, resistance to corrosion, and ease of cleaning. Other materials, such as copper, brass, and titanium, may also be used in specific applications. It’s essential to choose the right material for the job to ensure a high quality weld and maintain the safety and integrity of the product being transported.

Tips for preparing materials for sanitary welding

Here are some tips for sanitary tube welding:

- Proper preparation of the materials to be welded is essential for achieving a flawless finish. The first step is to clean the surface of the tubing thoroughly. Any dirt or debris on the surface can lead to a poor-quality weld.

- Ensure that the tubing is cut to the correct length and that the ends are square. This will ensure a tight fit between the two pieces of tubing and prevent any gaps or crevices in the weld.

- Ensure that the tubing is free of any burrs or jagged edges that can interfere with the welding process.

Practices for achieving a flawless finish

Achieving a flawless finish requires a combination of skill, precision, and attention to detail. Here are some best practices to follow when performing sanitary pipe welding:

- Use the correct welding technique for the material being welded. TIG welding is the most common method used for sanitary welding, but different materials may require different techniques.

- Use the correct filler material. The filler material must be compatible with the tubing material to ensure a high-quality weld.

- Maintain a consistent travel speed. A consistent travel speed will ensure an even weld and prevent any gaps or crevices.

- Use a back purge. A back purge is used to prevent oxidation on the inside of the tubing during welding, which can lead to contamination.

- Inspect the weld carefully. After welding, inspect the weld for any defects or imperfections. If necessary, rework the weld until it meets the required standards.

Troubleshooting common welding issues

Even with the best preparation and technique, issues can still arise during the welding process. Here are some common welding issues and how to troubleshoot them:

Porosity

Porosity is the presence of small holes or bubbles in the weld. It’s usually caused by contamination or improper shielding gas flow. To fix this issue, clean the surface thoroughly and adjust the shielding gas flow rate.

Cracking

Cracking can occur when the weld is subjected to too much stress or when the material being welded has inadequate ductility. To prevent cracking, ensure that the materials being welded are within the correct specification and use proper welding techniques.

Incomplete penetration

Incomplete penetration occurs when the weld doesn’t penetrate fully through the material being welded. This issue can be fixed by adjusting the welding parameters, such as the travel speed or current.

Safety practices for sanitary welding

Sanitary pipe welding can be hazardous if proper safety precautions are not taken. Here are some best safety practices to follow when performing sanitary welding:

- Wear protective gear. This includes gloves, aprons, and eye protection.

- Ensure proper ventilation. Welding produces fumes that can be harmful if inhaled. Ensure that the work area is well-ventilated.

- Use proper grounding. Improper grounding can lead to electrical shock or fire. Ensure that the welding machine is properly grounded.

- Follow proper electrical safety guidelines. Welding machines can produce high voltages that can be dangerous if not handled properly.

Resources for improving your sanitary welding skills

Improving your sanitary pipe welding skills requires practice and dedication. Here are some resources that can help:

- Online tutorials and courses. There are many online tutorials and courses available that can teach you the fundamentals of sanitary welding.

- Industry associations. Joining an industry association can provide you with access to training and resources to improve your skills.

- Mentorship. Finding a mentor who is experienced in sanitary pipe welding can be invaluable in improving your skills.

Final Thoughts

Sanitary pipe welding is a complex process that requires skill, precision, and attention to detail. By following the tips and tricks outlined in this guide, you can improve your skills and achieve a flawless finish. Always prioritize safety and to choose the right materials and techniques for the job. With practice and dedication, you can master the art of sanitary welding and ensure the safety and integrity of the pipe.