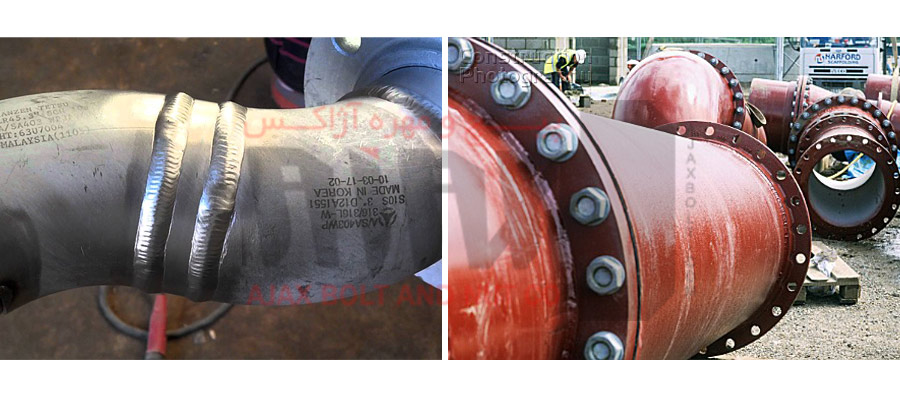

Welding creates a strong, permanent bond by melting materials. Bolting assembles components using fasteners, allowing for easy disassembly.

Welding and bolting are two common methods used in construction and manufacturing to join materials. Welding involves melting the materials to create a strong, permanent bond. This method is ideal for applications requiring high strength and durability. Bolting, on the other hand, uses fasteners like screws or bolts to assemble components.

This technique allows for easy disassembly and maintenance, making it suitable for structures that may need future modifications. Each method has its own set of advantages and disadvantages, depending on the specific requirements of the project. Understanding the differences helps in choosing the right method for your needs.

Welding Basics

Welding is a fundamental technique in construction and manufacturing. It involves joining materials, usually metals or thermoplastics, by melting the parts together and allowing them to cool, causing fusion. This method is essential for creating strong, permanent joints that can withstand high stress and pressure.

Definition And Process

Welding is the process of fusing two pieces of metal together. Heat is applied to the metal surfaces, melting them to form a single, strong joint. The most common types of welding include:

- Arc Welding: Uses an electric arc to melt the metals.

- MIG Welding: Uses a wire feeding gun that feeds wire at an adjustable speed.

- TIG Welding: Uses a tungsten electrode to produce the weld.

Each welding type has its own unique process and application. For example, arc welding is often used in construction, while TIG welding is ideal for precision work.

Common Applications

Welding is used in various industries, including:

- Construction: Welding is crucial for building bridges, skyscrapers, and pipelines.

- Automotive: It is used to manufacture and repair vehicles.

- Aerospace: Welding is essential for making aircraft and spacecraft components.

- Shipbuilding: Welders join steel plates and sections to form the hull of ships.

- Manufacturing: Welding is used in the production of machinery and equipment.

These applications highlight the importance of welding in creating durable and strong structures. It ensures safety, reliability, and longevity in various projects and products.

| Welding Type | Common Uses |

|---|---|

| Arc Welding | Construction, Shipbuilding |

| MIG Welding | Automotive, Manufacturing |

| TIG Welding | Aerospace, Precision Work |

Credit: www.ajaxboltco.com

Bolting Basics

Understanding bolting is crucial for construction and mechanical industries. Bolting is a common method to join two or more components securely. This section will cover the essential aspects of bolting, including its definition, process, and common applications.

Definition And Process

Bolting involves using bolts and nuts to fasten parts together. The process is simple and efficient. It consists of inserting a bolt through pre-drilled holes in the components. Then, a nut is threaded onto the bolt to secure the connection.

Here are the basic steps involved in bolting:

- Align the parts to be joined.

- Insert the bolt through the holes.

- Place a washer if needed.

- Thread the nut onto the bolt.

- Tighten the nut to secure the connection.

Bolts come in various sizes and materials, making them versatile for different applications. The choice of bolt depends on the type of load and environment.

Common Applications

Bolting is widely used across various industries due to its simplicity and reliability. Here are some common applications:

- Construction: Bolts are used to join steel beams, columns, and other structural components.

- Automotive: Bolts secure parts like engines, wheels, and chassis.

- Machinery: Bolts hold together different machine parts ensuring stability and function.

- Electronics: Small bolts are used in assembling electronic devices.

- Home Improvement: Bolts are common in furniture assembly and DIY projects.

Each application may require specific types of bolts, such as hex bolts, carriage bolts, or lag bolts. The selection depends on the requirements of the project.

Bolting offers the advantage of easy assembly and disassembly, making it a preferred choice for many applications.

Strength And Durability

The strength and durability of connections are crucial in construction and engineering. Both welding and bolting offer unique benefits. Understanding their differences helps in choosing the right method for your project.

Welding Strength

Welding creates a strong and seamless joint. The materials fuse at a molecular level. This fusion results in a connection often stronger than the base materials. Welded joints can handle high stress and pressure. They are ideal for applications requiring maximum strength.

Welded structures have fewer potential points of failure. The continuous connection distributes loads evenly. This makes welded joints highly durable over time.

Bolting Strength

Bolting provides a reliable and flexible connection. Bolted joints use mechanical fasteners like bolts and nuts. They are easier to inspect and maintain. Bolting is ideal for structures needing regular disassembly or adjustment.

The strength of bolted joints depends on the fasteners and materials used. Proper torque application is critical. Bolting can be a strong and durable option with the right specifications.

| Welding | Bolting |

|---|---|

| Fuses materials at a molecular level | Uses mechanical fasteners |

| Stronger than base materials | Depends on fastener strength |

| Handles high stress and pressure | Good for disassembly |

| Continuous connection | Easy to inspect and maintain |

Cost Considerations

When deciding between welding and bolting for construction projects, costs play a significant role. Each method has its own set of expenses, which can impact your budget. Below, we explore the various cost considerations for both welding and bolting.

Welding Costs

Welding involves joining metal pieces by melting and fusing them. This process requires specialized equipment, materials, and skilled labor. Here are the primary cost factors:

- Equipment: Welding machines, safety gear, and power sources.

- Materials: Welding rods, wire, and gases like argon or CO2.

- Labor: Skilled welders with certifications and experience.

- Preparation: Surface cleaning and alignment before welding.

- Inspection: Quality checks and possible rework.

The initial cost of welding equipment can be high. Training and safety measures also add to the expense. Welding often requires more time to complete, which can increase labor costs.

Bolting Costs

Bolting is a method of joining materials using bolts and nuts. This technique is generally simpler and faster than welding. Key cost factors include:

- Hardware: Bolts, nuts, and washers.

- Tools: Wrenches, torque tools, and drills.

- Labor: Less specialized workers can often do bolting.

- Preparation: Drilling or punching holes for bolts.

- Maintenance: Regular checks and tightening of bolts.

Bolt and nut prices are relatively low. The tools required are also less expensive compared to welding machines. Since bolting is typically faster, labor costs are reduced.

Here is a comparative table of the main cost factors:

| Cost Factor | Welding | Bolting |

|---|---|---|

| Equipment | High | Low |

| Materials | Moderate | Low |

| Labor | High | Low |

| Preparation | Moderate | Moderate |

| Inspection | High | Moderate |

Time And Efficiency

In construction and manufacturing, time and efficiency are crucial. Both welding and bolting have their unique advantages and drawbacks. Choosing the right method can significantly impact project timelines and overall productivity.

Welding Timeframe

Welding typically requires a longer setup time. Preparation is essential for quality results. The metal surfaces need cleaning, aligning, and clamping. The actual welding process can also be time-consuming, especially for large or complex structures.

Skilled labor is required for welding. This increases the overall time due to the need for precision and expertise. In some cases, multiple passes are needed to ensure strength and durability.

Below is a table comparing the time required for various welding techniques:

| Welding Technique | Time per Joint (minutes) |

|---|---|

| MIG Welding | 5-10 |

| TIG Welding | 10-20 |

| Stick Welding | 15-30 |

Bolting Timeframe

Bolting is generally faster than welding. Preparation is minimal, involving just alignment and hole drilling. The actual bolting process is straightforward and can be done quickly.

Bolting does not usually require highly skilled labor. This reduces the overall time and makes it more cost-effective. Bolts can be easily tightened using standard tools, making the process quicker.

Here is a list of the average time required for bolting:

- Aligning and drilling: 2-5 minutes

- Inserting bolts: 1-3 minutes

- Tightening bolts: 2-4 minutes

Efficiency is a key factor in choosing between welding and bolting. Understanding the time and labor requirements helps in making an informed decision.

Safety Concerns

Safety is crucial in both welding and bolting. Each method has its risks and must be handled with care. This section will explore the safety aspects of both techniques to help you choose the safest option for your project.

Welding Safety

Welding involves intense heat and sparks. Proper safety gear is essential to avoid burns and injuries. A welding helmet protects your face and eyes from bright light and sparks.

- Protective Clothing: Wear flame-resistant clothing.

- Ventilation: Ensure proper ventilation to avoid inhaling fumes.

- Gloves: Always wear heat-resistant gloves.

Electric shock is another risk in welding. Ensure all equipment is properly grounded. Keep your work area dry to avoid electrical hazards.

Bolting Safety

Bolting might seem safer but has its own risks. Improper handling can lead to injuries. Always use the right tools for the job.

- Eye Protection: Wear safety goggles to protect your eyes.

- Hand Safety: Use gloves to avoid cuts and bruises.

Over-tightening or under-tightening bolts can cause structural failures. Use a torque wrench to apply the correct amount of force.

| Safety Aspect | Welding | Bolting |

|---|---|---|

| Protective Gear | Helmet, gloves, flame-resistant clothing | Goggles, gloves |

| Risks | Burns, electric shock, inhaling fumes | Cuts, bruises, structural failure |

Environmental Impact

The environmental impact of construction methods is crucial. Both welding and bolting have distinct effects. Understanding these impacts helps in making informed choices for sustainable construction.

Welding Effects

Welding involves high heat and energy. This process uses electrical power, which often comes from non-renewable sources. The high energy consumption can lead to more carbon emissions.

Fumes from welding contain toxic metals and gases. These can harm the environment and human health. Proper ventilation and protective gear are essential to mitigate these effects.

Welding materials often require mining and refining. This adds to the environmental footprint. The process also generates waste like slag and spatter, which need proper disposal.

| Environmental Factor | Impact |

|---|---|

| Energy Consumption | High |

| Emissions | Moderate to High |

| Waste Production | Significant |

Bolting Effects

Bolting is generally less energy-intensive than welding. It doesn’t require high heat or electricity. This process relies on mechanical force instead.

Bolting produces fewer toxic fumes and gases. This reduces the risk of air pollution. The materials used in bolting, like nuts and bolts, are often recyclable.

However, bolting can still have environmental impacts. Manufacturing bolts and nuts involves resource extraction. This can lead to habitat disruption and pollution.

- Lower energy consumption

- Reduced emissions

- Recyclable materials

- Resource extraction impacts

Credit: www.innodez.com

Credit: diy.stackexchange.com

Frequently Asked Questions

What Are The Key Differences Between Welding And Bolting?

Welding fuses materials together, creating a strong bond. Bolting uses fasteners, allowing for easy disassembly. Welding is permanent, while bolting is more flexible.

Which Is Stronger: Welding Or Bolting?

Welding typically provides a stronger bond than bolting. This is due to the fusion of materials, creating a more unified structure.

When Should You Use Welding Over Bolting?

Welding is ideal for permanent, high-strength applications. Use it when disassembly is not required and maximum strength is essential.

Are Bolted Joints Easier To Maintain Than Welded Ones?

Yes, bolted joints are easier to maintain. They can be easily disassembled for repairs or modifications, unlike welded joints.

Conclusion

Choosing between welding and bolting depends on your specific project needs. Welding offers strength and permanence, while bolting provides flexibility and ease of assembly. Assess your requirements carefully to make the best decision. Both methods have their advantages and can be highly effective when used appropriately.

Make an informed choice for optimal results.